Whew!

Major milestones hit on the F kit today. Etchings proved, castings proved – so just production to go!

With the latest etching versions built, the chassis and long frame body etches are sweet. The short frame body will need one more revision, but this is very minor.

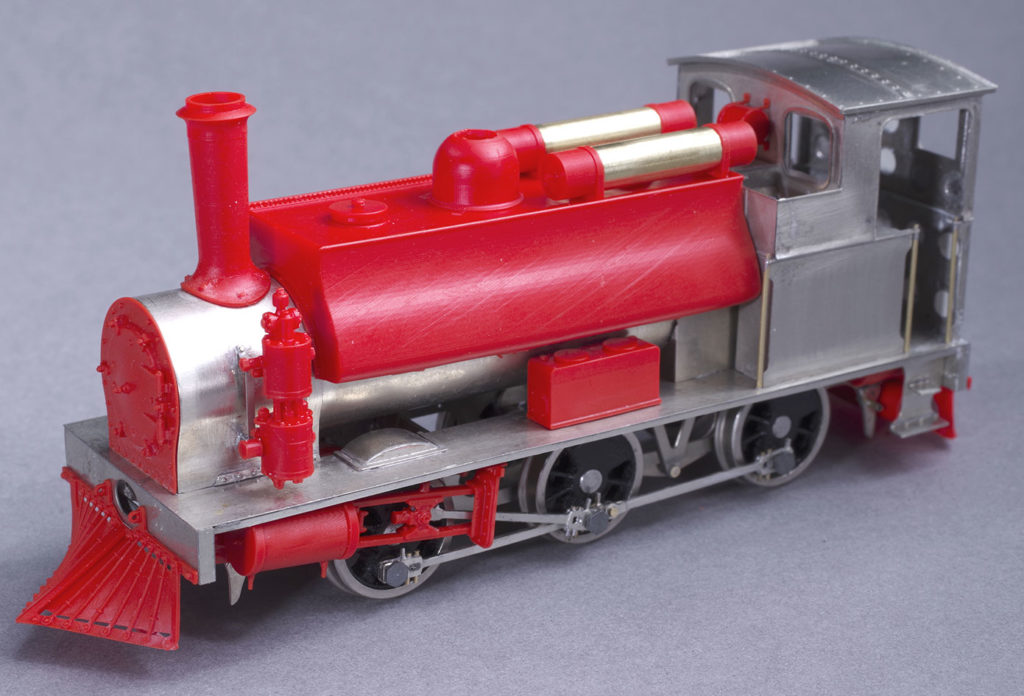

Having built the etches, the next task was to fit up the castings. To do this I used 3d resin prints for proving. These are easy to work with and ideal for testing without the cost and time required for getting brass castings. In the production kit most of the orange resin parts shown here will be in brass.

So here it is:

There’s still quite a few bits missing here, but it certainly looks like an F. This is the short frame Neilson version. Characteristics are the heavy slide bar hanger, flush riveted saddle tank and flush riveted scalloped cab side sheets.

A view of the top surfaces showing the tank top details. Also note the splasher. This is a neat fold clip construction that is quite straightforward to assemble. This view also shows the visual benefit of clear space under the boiler.

Earlier this week I spent some time at Ferrymead measuring up the air tanks on F13 – all five of them. Most of the major Westinghouse parts are shown in the photo, and all are test fitted to the loco here. The electrical components have not been fitted, but these are standard parts already proven on the W kit.

Another three quarter view. The cylinder assembly is in 3 parts – The cylinder proper, cylinder front with slide bars and hanger. These all locate into slots in the frames and just clip together. The final castings will need a little smoothing, but the design should be simple to assemble. There are also additional etched spacers to provide a little extra room if needed.

The parting shot. There is a wealth of detail in this kit, much of it still to be added to this build. But while fiddly, the parts all fit well with a minimum of fettling required.

1 comment