…and overflowing onto the kitchen table.

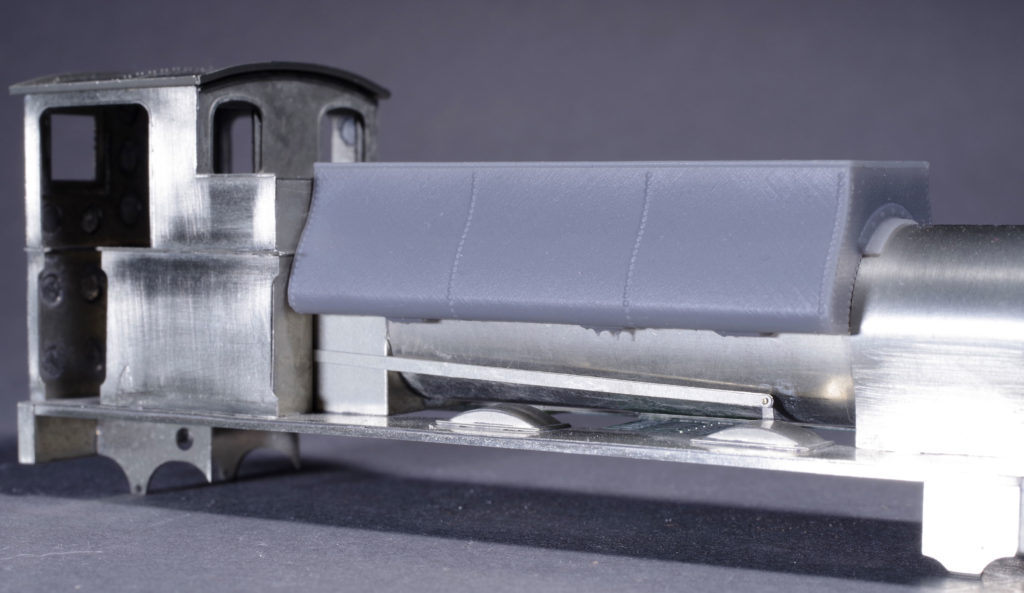

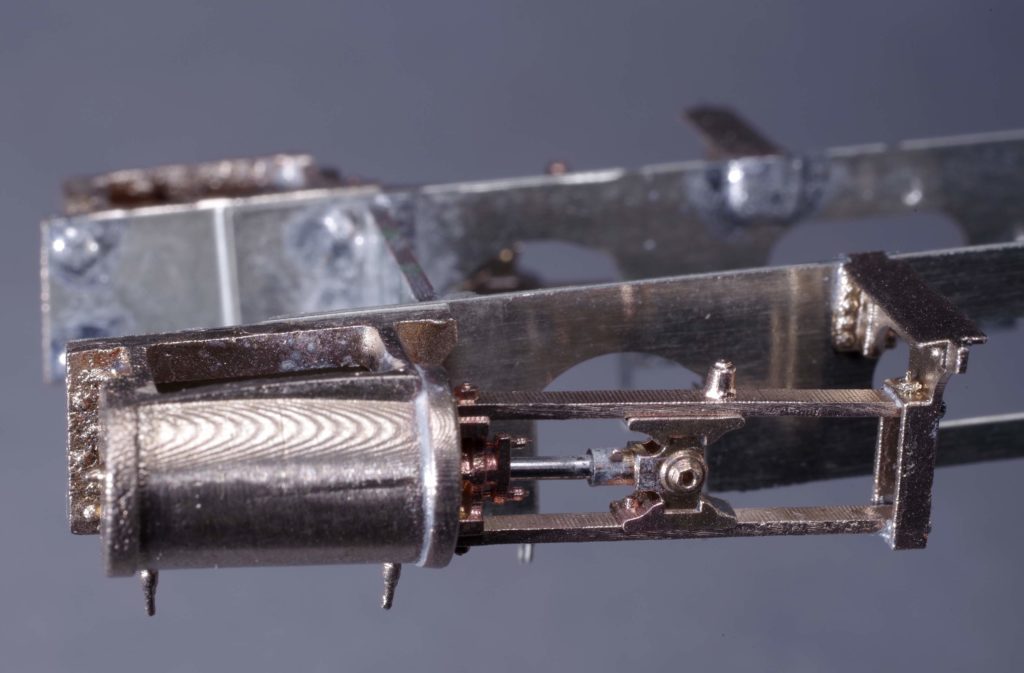

W locomotives. There are a number of Ws on the go at present. Just building the kit and doing something generic doesn’t seem to cut the mustard at chez NZFinescale so the opportunity has been taken to add a few additional castings for some details that were short lived or not normally modelled. Recent improvements in printing and casting have altered my approach to mechanical parts as well. I’m now printing slidebars, cylinders and crossheads that fit together beautifully with virtually no fettling. This represents a significant time saving over the etched slidebars of the kit that, while effective, are quite time-consuming to assemble. Likewise through holes are also casting true, which greaty simplifies assembly. I love building these kits as they are pretty low stress to get a fantastic outcome.

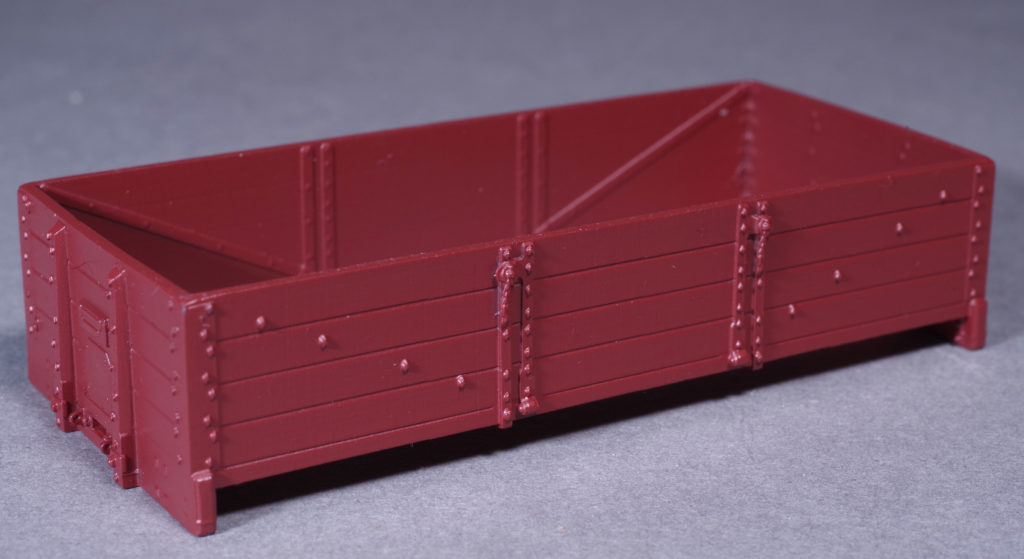

Fell Van F389. Following Peter Ross’ Fell van featured in the last blog post, I felt spurred to moving F389 forward as it had languished mostly complete in a box for some years. This van had unique strapping that is not covered in the kit so there was a little scratchbuilding required. Otherwise it is a straight kit build. It is just posed here at present as the roof and chassis are separate from the body. There is a bit of weathering planned before the glazing is added and the parts are joined up.

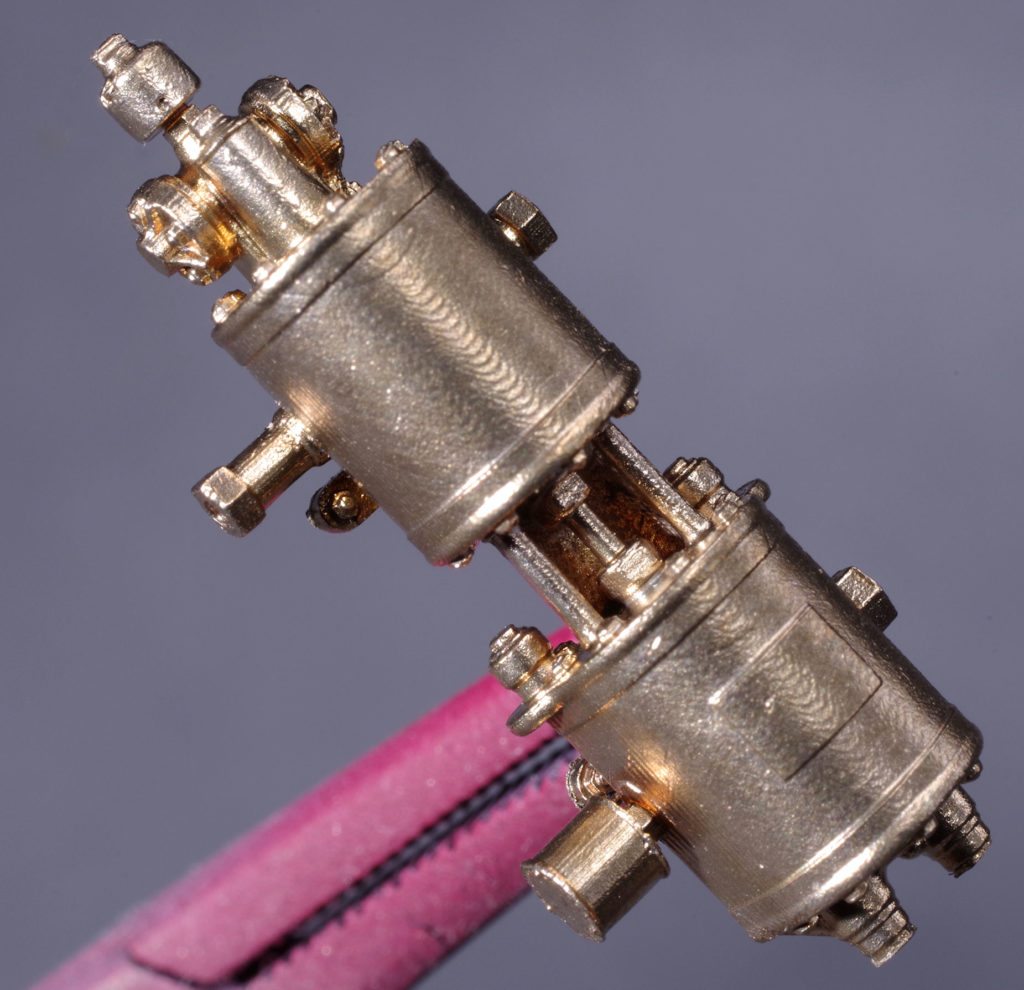

New Castings. Using the 3D printer to generate the sacrificial ‘waxes’ for investment casting into brass has been quite a learning curve. In principle, you just print the sprue and cast it, but in practice there is a lot more to getting good prints and castings. Fortunately, this is now happening far more often than it did 12 months ago. At present many of these new castings are not separately listed as products, having been developed for personal projects or kit components. However, any casting that appears in posts here or on our Facebook page is available to purchase on request. Many of these castings are available in multiple versions, to suit different situations. If you are building one of the smaller NZR steam locomotives or car and wagon stock there is a good chance that I have a bunch of the detail parts that you need.

F Kits. The F kits are very close. I’m in the process of final test builds and instruction writing. Production of the tanks has been recently sorted and I have revised the castings to make assembly easier. Most parts are on hand and I’m currently busy printing the casting ‘waxes’.

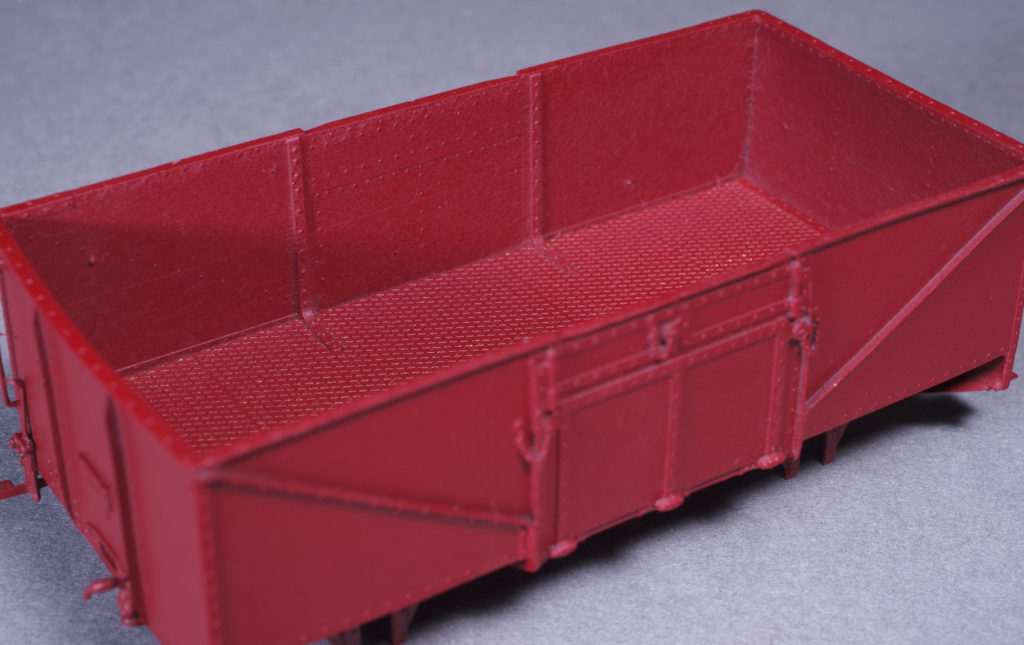

La and L wagon kits in 1/64. I’ve been threatening some new wagon kits for nearly a year, and work on these has been slowly progressing. The sticking point has been production of the bodies, which is now largely sorted. The basic principle was sorted ages ago, but production has been a little more problematic.

Etched underframes with full spring suspension are completed for the wooden L, LA-2, Q-1 and Q-4. Bodies for the L and LA are just being tweaked, but are largely finished and ready for production. The hoppers for the Qs are also well advanced.

One of the interesting features of digital bodies is the opportunity to play around with the the basic model and to produce versions really easily. This is all in the future for these wagons, but things like patches, loose/missing doors, alternative handgrabs, ‘battle damage’, alternative plate arrangements, doors posed open and so on are all intriguing possibilities.

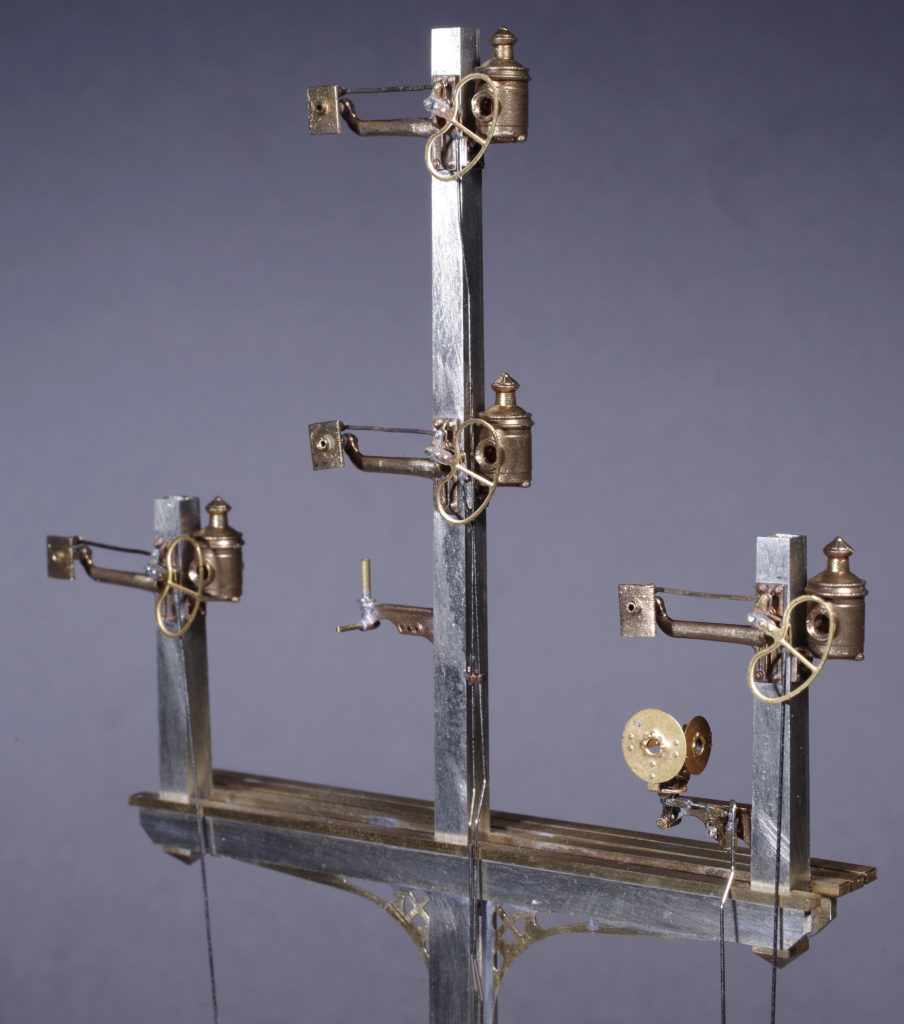

As a diversion I’m building a triple post semaphore signal with shunt discs. This has prompted some development over the existing kits with new castings replacing the old, as well as new cast parts that were previously etched. As a result the signal kits will likely be revised in future to be both easier to build and slightly more detailed. There will be a price rise with this however as the new parts are more expensive than the originals.

In other news, the old NZFinescale couplers are no more as the rubbers have been lost. However new castings are well underway and should be in the Emporium soon.

4 comments