Not NZ Labour party marketing, but the sentiment is probably similar to Adern’s. The W kit has been on the go longer than the incumbent government, so I’m in a mood to move on!

Over the last few weeks I’ve been putting together the initial batch of kits, writing instructions and other significant, but not especially blog-worthy, activities. I find kit manufacture to be a bit like parenting: rewarding, frustrating, emotionally draining, financially crippling, fascinating, educational… and I could go on. The balance must be on the right side of the life’s ledger though, as I’m still doing it (both parenting and kit-manufacture!).

There will be a product announcement page up soon further extolling the virtues of the kit and soliciting fiscal commitment for the privilege of owning, what I consider to be, the finest 1:64 NZR steam locomotive kit ever offered. Here’s why:

- I’ve used nickel silver for all the etchings. NS solders beautifully and more easily than brass as the heat transfer is less. It looks damn good too!

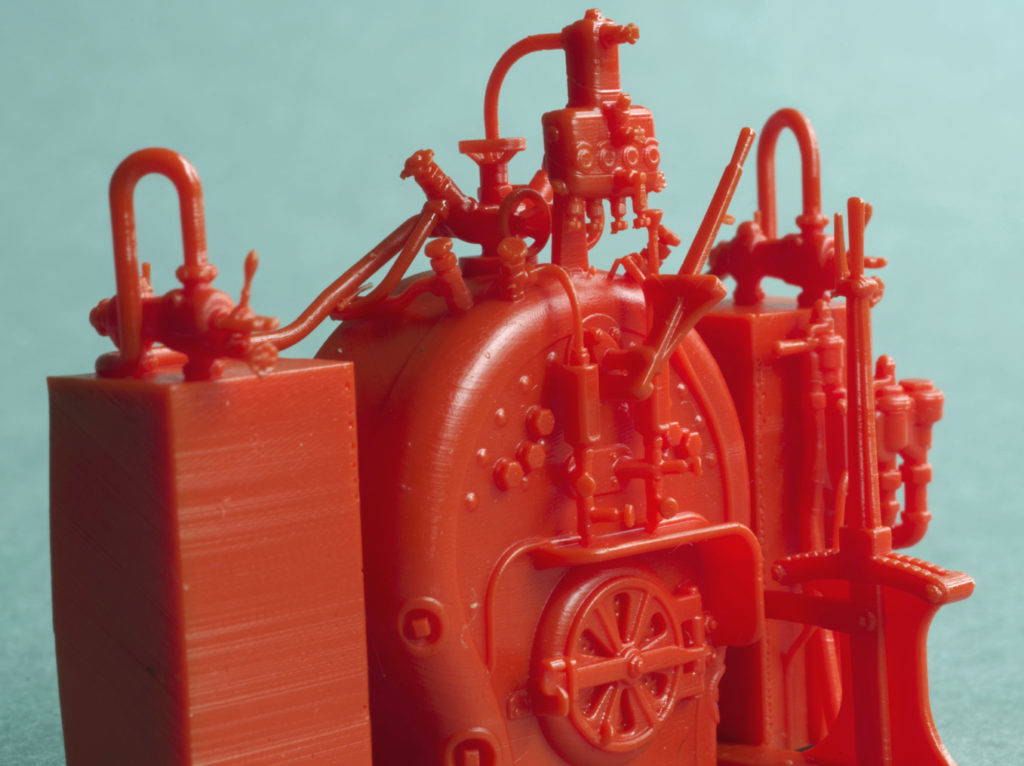

- Many of the castings are made directly from 3D prints. This has many advantages, including: Dimensional stability – without a wax step there is little shrinkage and the parts are generally more predictable; Unmouldable parts – the sophistication of the parts that can be cast is far greater than what can be routinely moulded; No part lines – There are none on these parts.

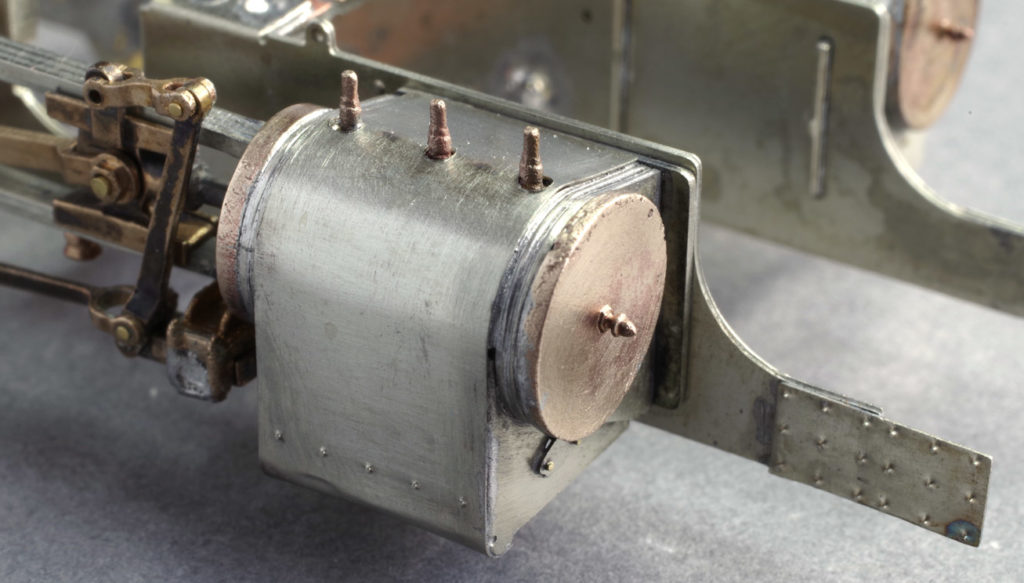

- Drive system. The drive system has been designed specifically for the W. From the coreless motor and ball races to the custom cut gears, the whole system has been designed from scratch to provide a smooth, quiet and slow drive.

- Level of detail – The photos below speak for themselves.

- Options. One of the advantages of the digital design/3D print/cast approach is the ability to viably offer a range of options. For example, W238 had a number of sand dome variants. We can supply any of these on request. Likewise if you want to build a locomotive at a specific date, just send us a picture and we will generally be able to supply the appropriate details to achieve that. The design of the etchings was also developed with flexibility in mind.

- Buildability. All parts for the kit have gone through multiple revisions to arrive at a result that is both accurate and buildable. The main etchings have tab/slot design that is self-jigging. There are a number of plastic parts that are screw together to assist in electrical isolation. Castings fit extremely well and require minimal clean up. There are 50 odd pages of illustrated instructions to guide the builder in how to achieve a great result too. The kit will require skill to build, but will reward that with a superb result.

The images below should convince you if you need it…

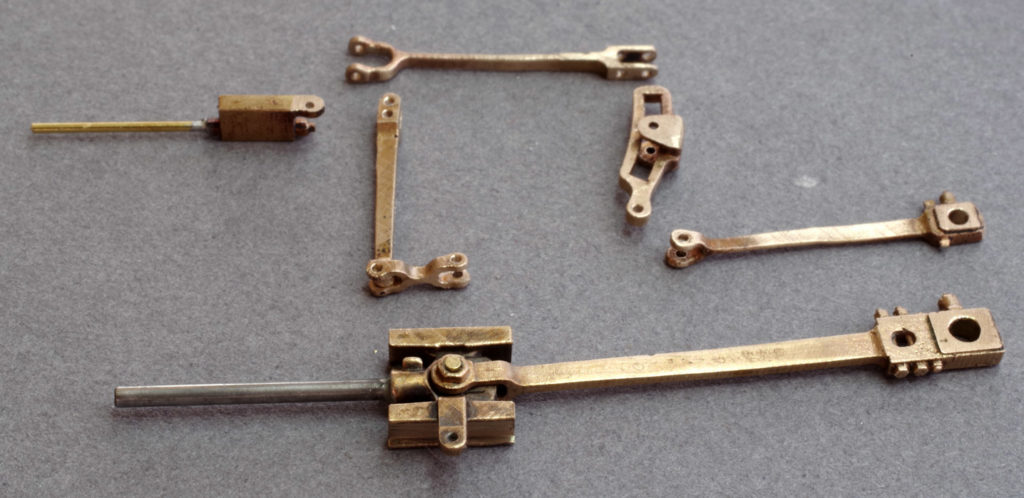

The valve gear parts. These are both accurate to the original drawings and detailed with bolts wedges and oil cups.

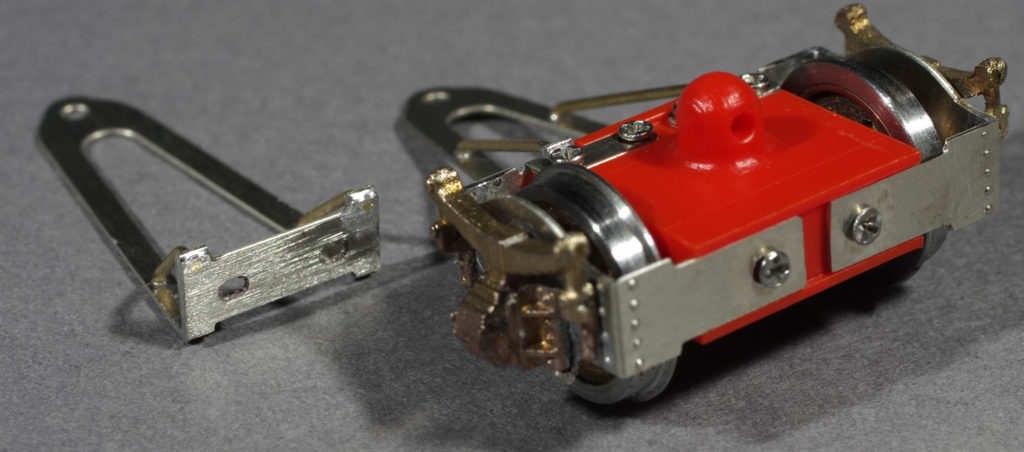

The trailing truck and front truck pivot arm. The design is easy to build, functional and adjustable.

I just love the little acorn on the cylinder cover. Being able to achieve this sort of detail is a huge step forward.

The air brake cocks well illustrate the level of detail that can be achieved with these techniques.

The latest version of the cab detail print now also includes the reverser. Every kit contains one of these one-piece prints for your delectation!

Production prints for W238 domes (left) and W192 domes (right). These will be cast directly into bronze.

Why the ‘W’ you might ask? I need both W192 and W238 for Rewanui. I wanted to do the best that I could. That required a 21st century approach and these kits reflect that commitment. The kit is the latest step in my modelling journey, but there are other things on the way. Enjoy!