In which your scribe continues his narration of the construction of We198…

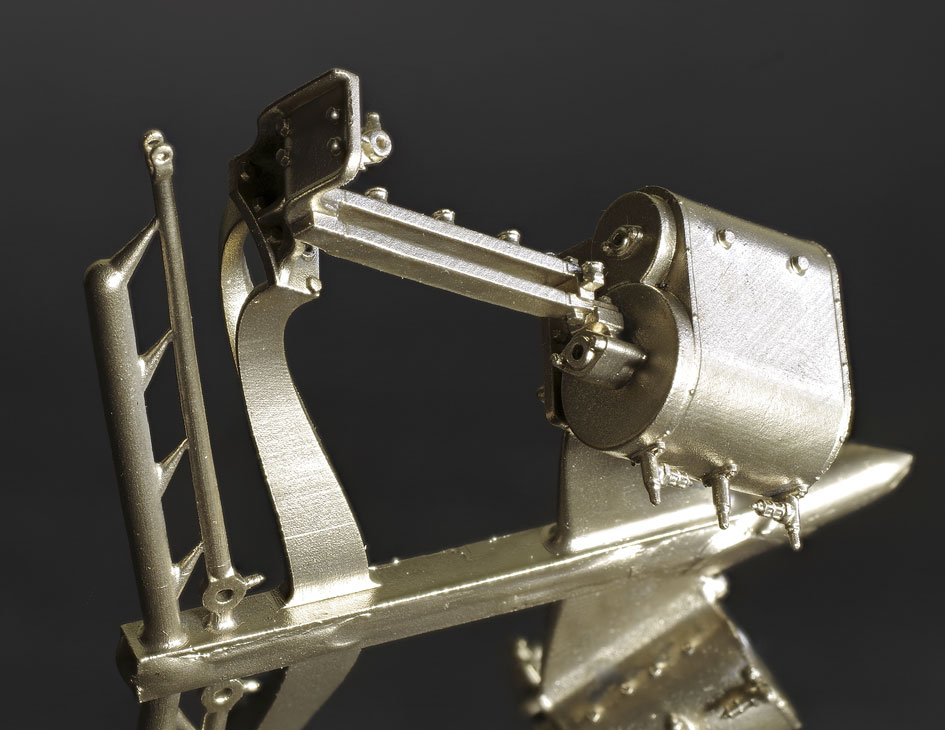

In the first thrilling instalment of this little exposition, I presented a CAD render of the cylinder and motion. Those parts have since been refined, printed and cast. The cylinder/slidebar/motion bracket were cast as a single part, as this simplifies construction significantly and provides a robust result. The outcome was rather good.

Two images on the cylinder casting. The front cylinder and valve chest covers were done separately as a) the print result (and thus casting) is better, and b) this allows easy access to the glands for clean up.

As part of the broader exercise I looked at the various brake bits as well. The We had a somewhat different arrangement to other locos I’m familiar with, and in any case I thought I’d try casting assemblies rather than fabricating them from etched cranks with wire and tube as I’ve done in the past. Again, it all worked rather well and it should be fairly easy to attach these parts to the frame for an effective look. The motivation here is twofold. Firstly I want something that looks as realistic as possible but, secondly, I also want to make things as easy as possible at build time.

Brake parts. At the bottom is the main brake crank on the fireman’s side, with the cylinder integrally cast. The middle part is the lever to the hand brake with the threaded portion of the handbrake attached. At the base of this part is a fork arrangement that bears on the pins of the first part. At the top is the small crank that’s part of the main brake shaft, with the barrel adjuster for the brake rodding attached. Also part of this sprue, and out of focus, are the hand brake pedestal and the Driver’s side parts.

Most of the castings are now done. There’s no pressure on the remainder as actual construction is still some way off.

While on the 3D modelling, however, I couldn’t resist having a play with the intricacies of the cab interior. Compared to the other locos that the layout needs, the Wes have generous cab windows and the back of the firebox will be relatively (though still not greatly) visible. The model is a speculative piece. The firebox dimensions are about right as I have a basic boiler drawing. The screw reverse (still fitted for my 1940 model) is according to the Sharp Stewart cab drawing which lacks full detail. The maintenance records provide some guidance on what was fitted and most of the individual parts are standard, and thus correctly dimensioned from other sources. The centre rail steam brake cock and pipework (above the flame plate) is based on a sketch from a driver. The ‘coffee pot’ oil can is from the standard drawing and I’m told they were often placed on the flame plate. There remains some guesswork, but I feel it’s a reasonable interpolation of what might have been.

On previous backheads that I’ve done the Detroit lubricator has probably been the bit I was least happy with and was the most variable in quality. This time around it is split in half, with the front printed as a separate part. This means the pipework at the back all self supports as it used to, but all the little fittings at the base of the lubricator form much more reliably and to higher quality.

In the warts and all image it’s tempting to bemoan the slight visible print lines. However on my PC the print looks like it is posed on a 10L can of Humbrol paint. On a real 14ml tinlet, the print lines are invisible – and will certainly not be distracting once the print is inside the cab.

The backhead. This was an opportunity to test some printing ideas and some painting thoughts. I see it as a test piece, but a successful one.

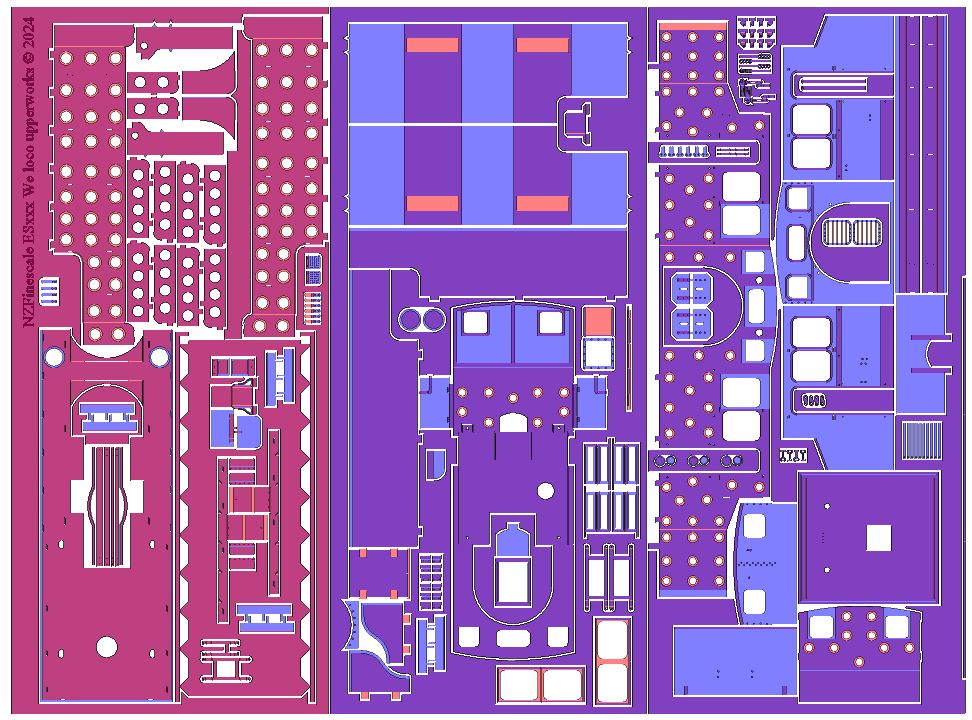

Having made inroads into all the castings, it was time to do the etches for the sheet metal. As usual the upperworks will be etched in 0.25mm nickel silver, while the underframe will be in 0.4mm n/s. It’s all drawn, and just awaiting final checking and some other artwork to accompany it for an economic batch. Not shown here are the chassis, boiler, smokebox and a number of alternate cab facings to allow construction of 375/376/377 in various guises. It all looks attractively, or frighteningly, comprehensive according to your disposition. Construction will be mostly self jigging with folds, slots and tabs. As with previous locos, the cab and tanks have a robust fold up substructure to which detail skins are attached. This is arranged to be done from the inside and should thus be invisible.

The embryonic We198, will probably gestate for a while now. It will likely be a couple of months before I have etchings on hand, and in the meanwhile there are some Was to do.